Trusted by organization & traning participants in over 45 countries

Traning | Certification | Education | Research

About IGMPI

The Institute of Good Manufacturing Practices India, an autonomous Institute recognised by Ministry of Commerce & Industry, accredited Vocational Institution of Ministry of Education, Government of India and approved by Food Safety and Standards Authority of India (FSSAI), presents a unique, friendly and interactive platform to get rid of all your GMP compliance related issues. GMP- an essential element of industries like pharmaceutical, cosmetic, Ayurveda, biotech, homeopathic, medical device and food manufacturing and sustainability services - in itself is the most dynamic part which witnesses frequent changes in terms of new rules being added and old ones being renewed. Thus, keeping oneself updated with current GMPs is essential to remain aligned with evolving industry requirement and standards.

Our team comprises knowledgeable professionals from diverse sectors such as Pharma, Healthcare, Food, Nutraceutical, Nutrition industries, pooling together their expertise, know-how, and practical experiences to create this GMP guide. IGMPI is moving hand in hand with technology advances and has gained recognition as a stronger and better education and training platform provider for professionals and students in the areas of GMP, Quality Assurance and Control, Pharma, Food & Nutrition, Environment and Healthcare Regulatory Affairs, Clinical Research, Pharmaceutical IPR and Good Laboratory Practice and Product Management. Our board of governors and specialists have collated their acumen and are offering state-of-the-art courses which includes GMP training, Quality Assurance and Control, Pharma and healthcare Regulatory Affairs, Clinical Research, Pharmaceutical IPR, Environment Social Governance (ESG), and Good Laboratory Practice in form of formal classroom studies, online/interactive programmes, online seminars, as well as onsite training programmes along with the knowledge of worldwide affairs of the industry. In short, a round-the-clock service is provided for any information in these areas required by anybody from around the country and abroad. Based on high standards of quality, the training programmes in Pharma, Healthcare and Food GMP, Quality Assurance and Quality Control, Regulatory Affairs, IPR, Pharma Product Management, Public Health, Hospital Management, Clinical Research, Pharmacovigilance, Medical Writing, Medical Coding, Nanotechnology, Drug Design and Discovery, Food QA&QC, etc., areas have been approved by Quality Council of India, which is an autonomous body and an accreditation authority for education & vocational training providers under the Ministry of Commerce & Industry, Government of India. IGMPI is duly licensed and certified by Bureau of Indian Standards (BIS) under Bureau of Indian Standards (Conformity Assessment) Regulations 2018.

Accreditation and Awards

IGMPI is recognized by the Ministry of Commerce & Industry, Government of India and duly licensed and certified by Bureau of Indian Standards (BIS) under Bureau of Indian Standards (Conformity Assessment) Regulations 2018 (License number: ERO/EOMSM/L-8000027) for offering education and training programmes, services and processes in the areas of Pharmaceutical, Food, Nutrition, Healthcare, Environment Health & Safety (EHS), Environmental Social & Governance (ESG) and Marketing Communications.

IGMPI is an accredited Vocational Institution of the Ministry of Education, Government of India Institute of Good Manufacturing Practices India is Management System (QMS) certified under NABCB accreditation. IGMPI is also approved by Food and Life Sciences Sector Skill Councils recognized by the National Council of Vocational Education and Training (NCVET).

IGMPI is an accredited Vocational Institution of the Ministry of Education, Government of India Institute of Good Manufacturing Practices India is Management System (QMS) certified under NABCB accreditation. IGMPI is also approved by Food and Life Sciences Sector Skill Councils recognized by the National Council of Vocational Education and Training (NCVET).

1. Course Content

2. Course Design

3. Course Material

4. Instructors

5. Class size & Attendance

6. Facilities

7. Evaluation of Students

8. Written Examination

9. Certificate

The Post Graduate and Executive Diploma programmes of IGMPI in Good Manufacturing Practices, Regulatory Affairs, Intellectual Property Rights, Quality Assurance and Quality Control, Public Health, Nanotechnology, Hospital Management, Product Management, Sales and Marketing Management, Clinical Research, Medical Writing, Drug Discovery and Development, Pharmacovigilance, Medical Coding have been duly assessed and approved by Quality Council of India, Government of India based on fulfillment of QCI's following criteria:

IGMPI is also approved by Food Safety and Standards Authority of India (FSSAI) (FSSAI ID: TPINS18). IGMPI® is licensed by Department of Food Safety & Drug Administration under the Drugs and Cosmetics Act, 1940 and registered under Food Safety and Standards Act 2006.

IGMPI is also approved by Sector Skills Council under National Skill Development Corporation (NSDC) setup by Ministry of Skill Development & Entrepreneurship, Govt of India.

IGMPI has been conferred with the prestigious "BUREAU OF INDIAN STANDARDS (BIS) AWARD OF HONOUR 2023". QUALITY COUNCIL OF INDIA (QCI) has also conferred IGMPI with D.L. SHAH NATIONAL QUALITY AWARD, Certificate of Merit & ASSOCHAM has conferred IGMPI with the Services Excellence Award based on excellence of its services to the students and training participants.

IGMPI's Membership with IPA

IGMPI is a Lifetime Institutional member of Indian Pharmaceutical Association (IPA).

Bureau of Indian Standards (BIS)

Bureau of Indian Standards (BIS) came into existence through an act of Parliament in 1987. BIS is the National Standard Body of India established under the BIS Act 2016 for the harmonious development of the activities of standardization, marking and quality certification of goods and for matters connected therewith or incidental thereto. The Bureau is a Body consisting of 25 members representing both Central and State governments, Members of Parliament, industry, scientific and research institutions, consumer organizations and professional bodies; with Union Minister of Consumer Affairs, Food and Public Distribution as its President and with Minister of State for Consumer Affairs, Food and Public Distribution as its Vice-President.

Quality Council of India (QCI)

Quality Council of India is set up by the Government of India to establish and operate national accreditation structure and promote quality through National Quality Campaign. QCI is registered as a non-profit society with its own Memorandum of Association. QCI is governed by a Council of 38 members and Chairman of QCI is appointed by the Prime Minister on recommendation of the industry to the government. The Department of Industrial Policy & Promotion, Ministry of Commerce & Industry, is the nodal ministry for QCI.

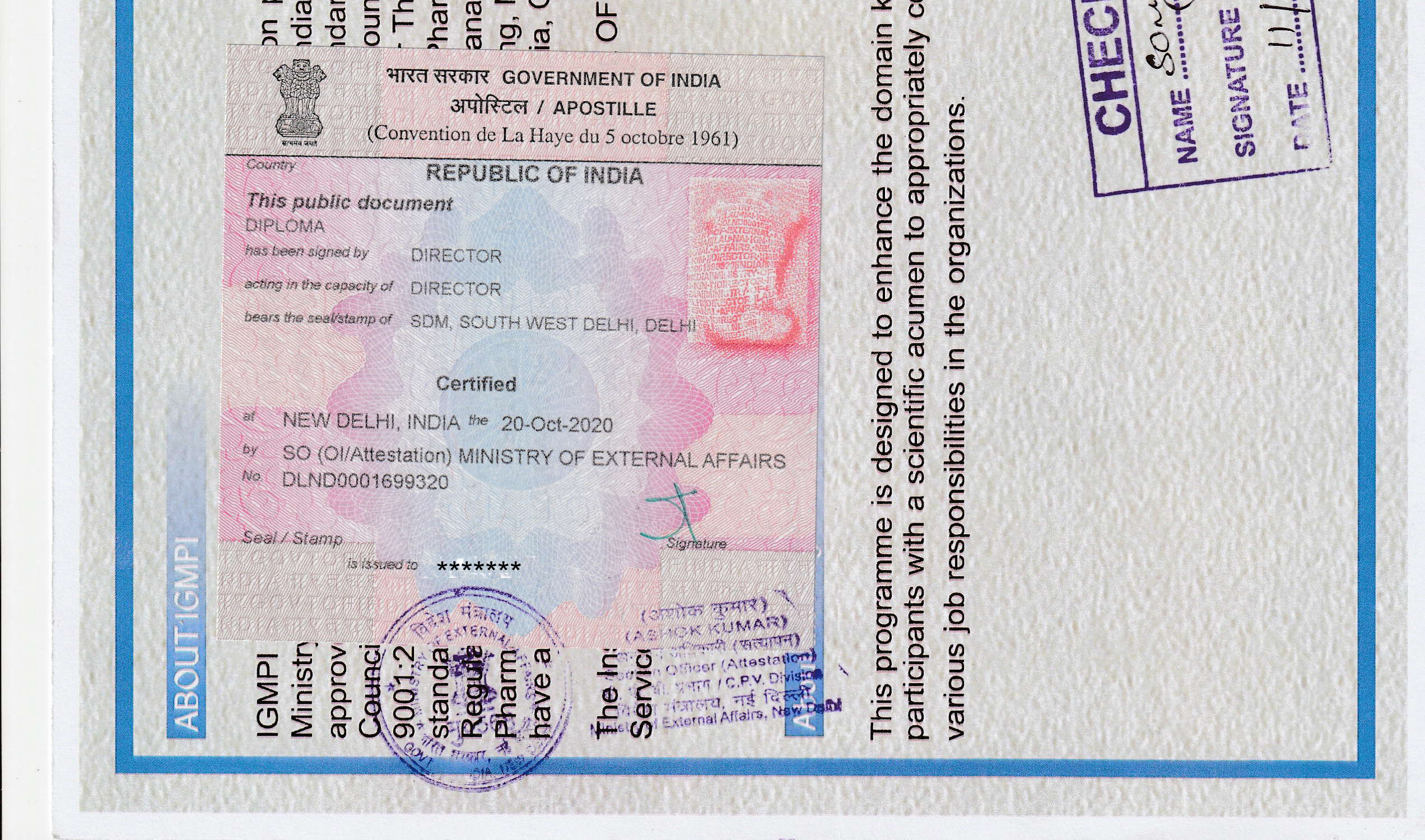

International Recognition

For providing its education and training services to overseas students, IGMPI is registered with the Directorate General of Foreign Trade, Government of India and our Export Import Code is AADCI7680Q.

IGMPI is an Institutional Member of the International Society for Quality in Health Care

Bureau of Indian Standards (BIS) is a member of International Organization for Standardization (ISO) and through the Indian National Committee (INC) which is a member of International Electrotechnical Commission (IEC). BIS is also a member of regional standards bodies like Pacific Area Standards Congress (PASC) and South Asian Regional Standards Organization (SARSO). India started taking part in IEC from 1911 and subsequently the then Indian Standards Institution (now BIS) took over the responsibility of Indian National Committee of IEC(INC-IEC) in 1949. Since then the INC-IEC is actively participating in the activities of the IEC both at the policy level and technical work and carrying out the responsibilities as member body of IEC Council. India is a member in Standards Management Board (SMB) of IEC since 2015.BIS has also signed Bilateral Cooperation Agreements (BCA)/Mutual Recognition Agreements (MRA) with the National Standards Bodies of several countries like Afghanistan, Bangladesh, Belarus, Egypt, European Union , Germany, Ghana, Greece, Indonesia, Iran, Japan, Jordon, Kenya, Kyrgyzstan, Mali, Mauritius, Nigeria, Russia, Saudi Arabia , Slovakia, Slovenia, Suriname, USA, UAE, Uzbekistan, Viet Nam, Bhutan, Brazil, Israel, Nepal, Pakistan and Sri Lanka.

National Accreditation Board for Certification Bodies (NABCB), Quality Council of India is a member of International Accreditation Forum (IAF) & Pacific Accreditation Cooperation (PAC) as well as signatory to its MLAs for Quality Management Systems, Environmental Management Systems and Product Certification. NABCB is also a Full Member of International Laboratory Accreditation Cooperation (ILAC) & Asia Pacific Laboratory Accreditation Cooperation (APLAC) as well as signatory to its MRAs for Inspection.

Programme Fee Details

| S.No. | Programmes | Duration | Mode | Programmes Fee |

|---|

Advisory Board and team

Our Advisory Board Members : https://igmpi.ac.in/our-advisors-and-team

Institute of Good Manufacturing Practices India

C-6, Qutab Institutional Area, Near Old JNU Campus, New Delhi–110016, India.

18001031071

(Toll Free -9:00 am to 5:30 pm IST-except on Central Government holidays)/

info@igmpi.ac.in